The standard sandwich panel is also known as the composite panel and consists of two parallel sheets that contain an insulating material in between. Thinness is one of the main characteristics of the sheets, and these sheets are not very thick by themselves; But the combination of layers and insulation between them creates a light but at the same time rigid composition. In fact, the competitive advantage of this product is that the technical characteristics of metal and insulation are integrated and the combined structure will have valuable advantages in all respects. What you read in this article is an important part of the properties and advantages of standard sandwich panels, knowing them will ensure a smart choice for covering the shed or production hall.

In order to make a standard sandwich panel, coated metal sheets should be used that are covered by appropriate coatings. These sheets are sometimes even used alone to cover the roof of the shed, and this time by being in the sandwich panel structure, they create a product with greater strength and more benefits; A product whose three key components should be considered “inner sheet”, “insulating material” and “external sheet”. The standard sandwich panel in its current form was introduced to the construction market in 1960 and has continued to grow as a widely used element in the market. These panels are used in today’s construction to cover walls and ceilings, and in this respect, there is no difference between industrial structures and commercial buildings.

Standard sandwich panel strength and easy to carry

When designing, regardless of whether the relevant product is going to be used in the wall or roof of the shed, it should be noted that the panels must be strong enough to withstand the incoming forces. There are many forces on the standard sandwich panel, the most important of which are as follows:

- Load due to the panel’s own weight: Sandwich panels must be strong enough to support their own weight.

- Loads caused by wind, snow and rain: depending on the geography and environmental conditions, the strength of the panel should be managed.

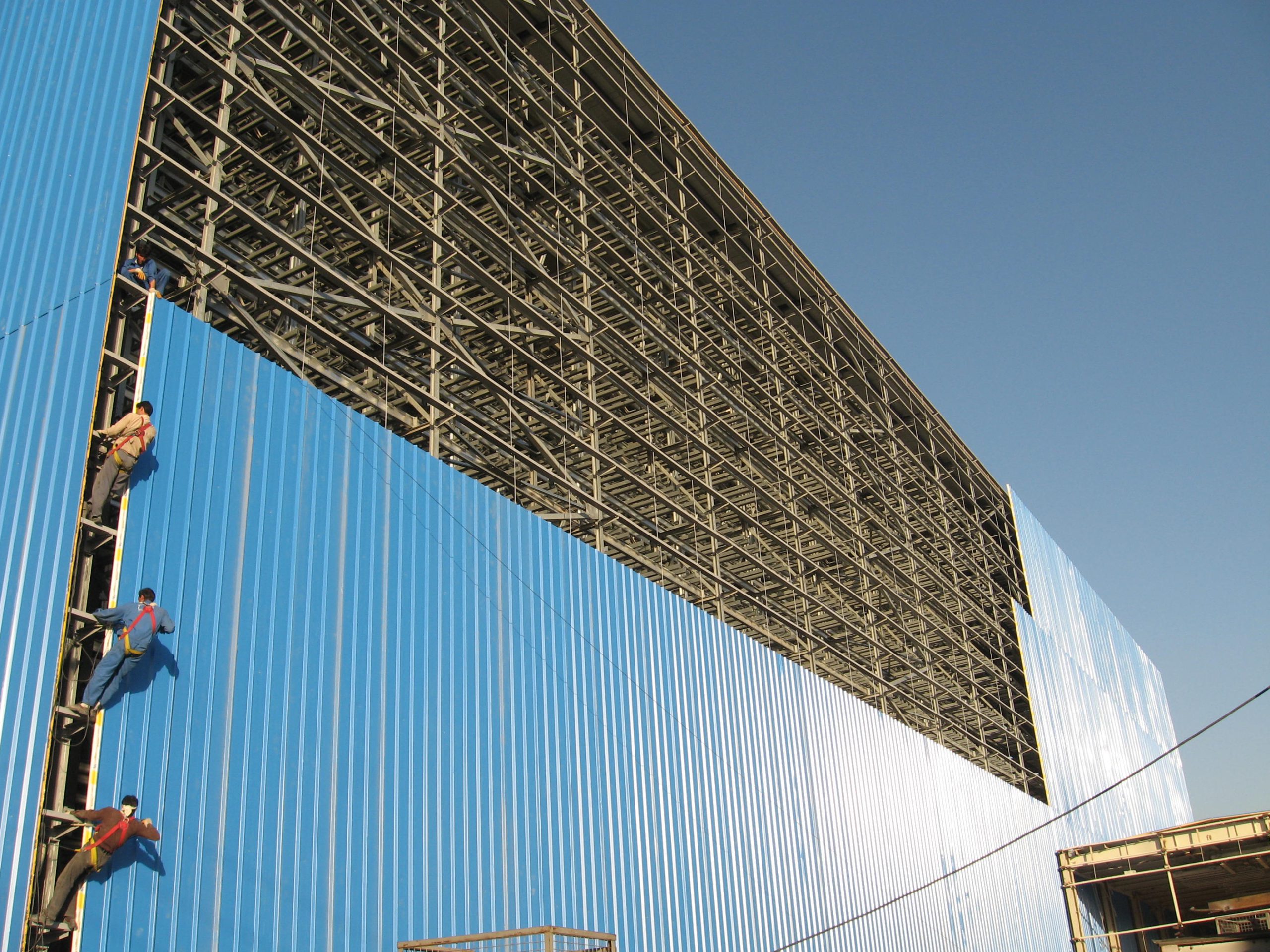

- Loads during installation: This product should not be damaged by any pressure during installation.

The selection of the top and bottom sheets as well as the selection of the material and thickness of the middle insulation is done in such a way that the produced panel can have the necessary resistance and strength against the result of the forces coming from all three categories. Another point that must be considered is the temperature difference and, as a result, the expansion and contraction that will occur in the metal frame; Obviously, if this issue is not observed, even this product will likely suffer serious damage and destruction. To compensate for this, the installation details are adjusted so that each panel has a two-way freedom of movement so that it can easily expand or contract.

Standard sandwich panel against wind and rain

In addition to paying attention to the flexibility of the joints used in sandwich panels, the sealing and air sealing of these products should also be considered, and this issue is considered a main and fundamental issue in the implementation of various types of thin coatings such as sandwich panels. Because these coatings expand and contract faster compared to roofs covered with bricks or prefabricated concrete, which is called destructive temperature difference. The old coverings that used traditional materials absorbed water and were known as water-absorbing covering materials.

But non-absorbent surfaces such as metals and glass cause water to flow on the surface, which increases the risk of water leaking behind the cover and inside the space. For this reason, all the seams of the standard sandwich panel, which are prone to water penetration (especially in rainy areas), will be sealed first and then they will install rain catchers on them. It is not bad to know that ordinary sealants are quickly destroyed by sunlight and weather changes and suffer from quality loss, so they are not suitable for sandwich panels at all.

Sandwich panel style thermal insulation

The issue of managing energy consumption and preventing wastage of resources is one of the concerns of today’s world, and the world of industry is no exception. The energy consumption of buildings, both industrial, commercial and residential, has a significant effect on this issue; Because buildings have a very high energy consumption, which depends on many factors.

One of these factors is preventing heat exchange between the inside and outside of the structure. Standard sandwich panel can be considered a very suitable insulation for heat due to the existence of an insulating core between two metal plates. But a very important point that should be taken into account in this field is to avoid thermal bridges in the design and implementation of the panel as much as possible. Thermal bridging means the physical connection between two metal layers, which must be prevented.

Acoustic sandwich panel

The amount of sound transmission and sound reflection from the standard sandwich panel to the outside is a very important indicator that should be well considered. The intensity of transmitted sound in industrial environments depends on the background noise; This means that the higher the background noises, the less annoying industrial noises will be.

Sound is transmitted in two ways: airborne (transmission through air molecules) and impact (transmission through frame to frame of the structure), in both cases, the insulation in the sandwich panel is capable of good resistance to sound propagation. to show The greater the overall thickness of the standard sandwich panel, the better overall sound insulation.

Usually, if the material and thickness of the sheet is chosen carefully and the type of insulation and the diameter of the foam used are selected correctly, this shed cover is able to provide a good acoustic standard. If reducing the sound reflection inside the hall is of particular importance to you, we recommend that you definitely use a panel with an internal mesh surface that has a brilliant performance in sound absorption.